Why Firebird Is Trusted By 160 + Customers

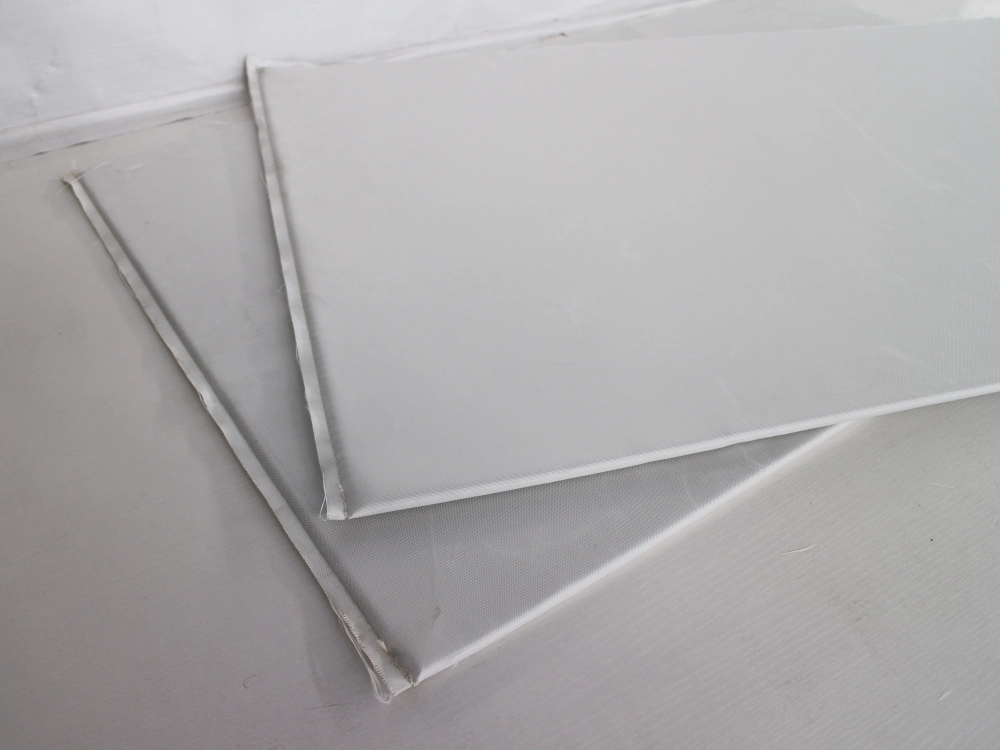

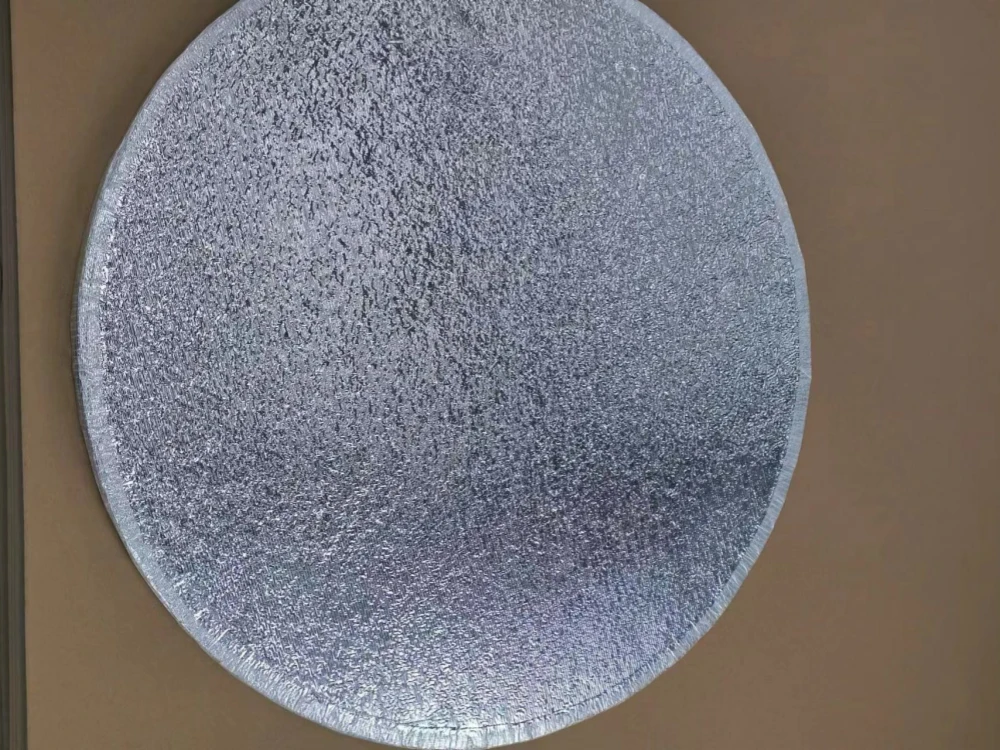

Microporous Board

MIP-950 Microporous Board is a standard-grade, high-performance insulation product made from 7-12 nm…

MIP-950HY Microporous Board is a hydrophobic insulation solution specifically designed for…

MIP-800 Microporous Board is a cost-effective insulation solution specifically designed for low-temperature kilns…

Flex Microporous Panel is custom made flexible microporous insulation panels with very good thermal properties.

Microporous boards are widely used in industries where high-temperature …

Microporous VIP Core is a high-performance insulation solution designed for space-efficient…

Firebird Consultant Team

Worked in Nikolaus Sorg GmbH more than 50 years. Know how on glass furnace design and refractories for glass furnace.

31 years experience at the Research & Engineering Department in Sisecam, 6 years as Manager of Melting Technologies Division.

Former member of the board in P-D Refractories CZ, renowned expert on glass furnace refractories production and marketing.

20 years experience at the Research & Engineering Department in Sisecam, 19 years in HEM Engineering Consulting as M.D.

Applications of Microporous Board

Firebird works with qualified manufacturers under controlled formulations and stable processes, providing:

- Batch inspection records for key physical and thermal properties;

- Dimensional and visual checks with pre-shipment photos;

- Third-party test reports when required;

- Clear batch identification and traceability, from production to packing.

This documentation-driven process helps technical, quality, and commercial teams align faster, shortens approval cycles, and supports audits and repeat orders.

Firebird is situated in Zhengzhou, Henan Province, at the heart of the world’s refractories base. With over 700 refractories manufacturers nearby, our location provides convenient access to different kinds of refractories. Additionally, we are approximately 2.5 hours away from Beijing and 5 hours away from Shanghai by high-speed train. For international travelers, Zhengzhou Xinzheng International Airport (CGO) offers flights to nearly all major cities in China, as well as several international destinations.

Yes, we provide free samples for testing purposes. However, customers are responsible for covering the courier charges associated with shipping the samples.

Absolutely! We welcome plant audits and visits to our facilities. Please note that Firebird insulation refractory and high-performance refractories are manufactured in separate plants. Let us know your requirements, and we can arrange a convenient schedule for your visit to ensure a smooth and informative experience.

To receive a quick and accurate quote, please provide us with the following details: Material list, Dimensions or drawings, Technical Data Sheet (including Chemical and Physical properties), Quantity, and your preferred Price terms. Once we have this information, we will respond with a quote as soon as possible.

Our standard delivery time is generally between 10 to 15 days for most products. However, for specialized or customized bricks, the delivery time may extend to approximately one month. We strive to meet our customers’ timelines and will provide an estimated delivery date upon order confirmation.

We accept payments via T/T (Telegraphic Transfer) in major currencies such as Euro (EUR) and US Dollar (USD). Our payment terms are flexible, and we can accommodate different payment schedules based on the agreement.

Investing in Insulation: A Story for Every Furnace

Think of your furnace as a hardworking machine that have two important layers: the working layer, which faces the heat directly, and the insulation layer, which quietly helps by saving energy and lowering costs.

Many people see insulation as just another cost, but experienced furnace operators know it’s more than that—it’s an investment in keeping things efficient and reliable. Once you put insulation in, it stays there for years, working quietly in the background. If your energy costs go up because of poor insulation, you can’t just replace it right away. That’s why choosing good insulation from the start can save a lot in the long run, by keeping energy costs down and helping your furnace last longer.

At Firebird, we focus on insulation refractory, which makes us different from suppliers who sell dense refractories only. This focus helps us give you the best solutions for all types of furnaces, from glass and steel to aluminum and cement. Choosing quality insulation means better energy savings, more money saved over time, and less impact on the environment.

The insulation layer may not be in the spotlight, but it’s key to helping your furnace work its best. Make a smart choice, and you’re not just saving heat—you’re getting the most out of your whole operation.